Those responsible for the management of cleaning and disinfection in a food processing operation often do not fully understand the reasons for plant hygiene or the scientific principles and technology behind effective cleaning. This is essential in order to comply with legal and technical standards and ensure food hazards are controlled.

This whitepaper deals with the essential knowledge required for effective cleaning programs within a food processing operation including reasons for cleaning, the chemistry, principles of disinfection, equipment and methods, GFSI requirements and monitoring of hygiene.

Reason for Cleaning and Disinfecting

Food safety management systems often place HACCP at the centre of control for specific food hazards. This makes sense, particularly where a specific hazard linked to adverse impacts for the consumer can be identified. However, no matter how robust the HACCP system, maybe it requires a sound program of basic controls that address general hazards, many of which may not be identified. These programs are described as Good Manufacturing Practices (GMP), Pre-requisite Programs (PRP) and Control Points (CP), to name a few. Regardless of the term used, they all represent the essential requirement for good practice to provide a safe environment for the manufacture of food. Among the most important of these is the need to clean and sanitise your plant and equipment sufficient to produce food free of physical, allergenic, chemical and microbiological hazards. Besides, employees must understand the reasons why a food plant must be cleaned. Simply instructing people is seldom enough to maintain high standards – they must also understand the reasons why including:

- To reduce the risks from food hazards – food poisoning and foreign body contamination.

- To comply with local and international legislation.

- To meet specific customer requirements.

- To meet the requirements of global food safety standards (GFSI).

- To maintain complimentary audit and inspection outcomes.

- To allow maximum plant productivity.

- To present a hygienic visual image.

- To promote safe working conditions for staff, contractors and visitors.

- To maintain product shelf-life

- To avoid pest infestation.

- At the most basic level, the visual appearance of a food factory is an indication of the standards and culture of the company. It has a substantial impact on the perception of an auditor or visitor and can influence the overall outcome of audits and securing new business. For this reason, the visual cleanliness of a company is as crucial as detailed HACCP plans.

- Cleaning costs money. It is often perceived as a necessary evil which does not add value to a product directly. The cost of cleaning and indeed, the cost of not cleaning is seldom measured routinely by food companies. The typical cost elements of a cleaning programme include:

- Labour and supervision

- Water supply, treatment and purchase

- Water heating

- Cleaning equipment

- Chemicals

- Corrosion

- Monitoring

- Effluent

- Downtime

Of these, labour is usually the most significant factor accounting for over 60% of the total cleaning budget, whether resourced under contract or in-house. When cost pressures come to bare, usually labour is normally cut back. While this may save money in the short term, over time, it will lead to a number of indirect costs including a reduction in shelf life, increase in product complaints, recalls, regulatory restriction and a loss of business. The viability of the business will ultimately be impacted. The next most significant costs are water and chemicals which can vary depending on the source and supplier. In this paper, we will cover some of the factors impacting on cleaning and associated costs.

Cleaning

Cleaning is a physio-chemical process involving a number of factors.

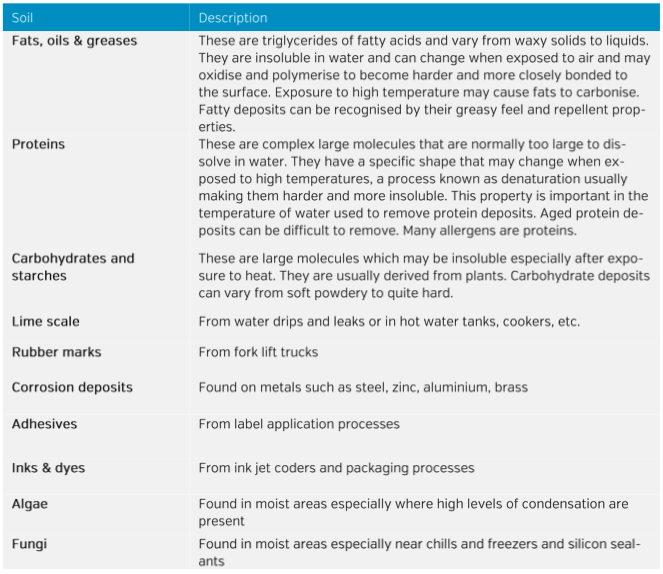

Soil

In food processing operations soils and deposits originate from the ingredients used in the preparation of the product. These soils include the following:

Not all the deposits mentioned pose a serious risk; however, all create a poor visual appearance. Some act as an excellent substrate for absorbing other soils and micro-organisms. The critical point is that each is chemically different and requires different cleaning methods. Therefore, it is essential to identify the typical soils present and design your program accordingly.

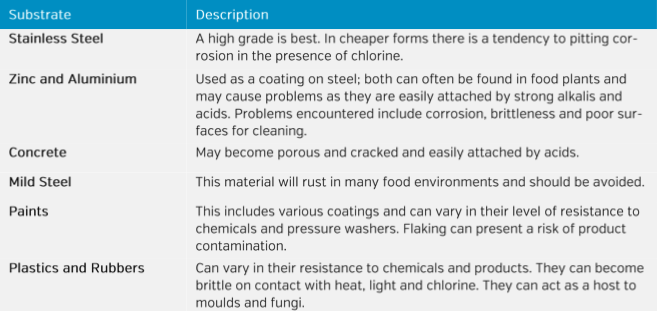

Substrate

The substrate is the materials of construction found in food processing plants. The standard of materials can vary with their ease of cleaning and resistance to corrosion with chemicals. The ideal material standard is smooth, non-porous, abrasion-resistant and inert.

When selecting surface materials, you should ensure they are compatible with the chemical and physical production environment. Prevention of product contamination risks should always be considered when reviewing the specification of materials.

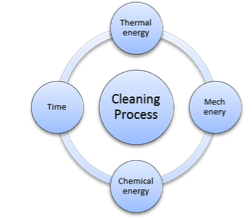

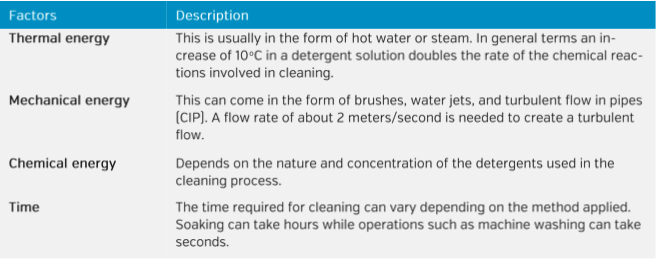

Cleaning Energies

Energy is the core driver behind all cleaning processes. This energy is usually made up of a combination of factors, as seen in the illustration.

It is the interaction of the above factors that determine the effectiveness and rate of the cleaning method. Often the aim is to obtain a balance consistent with cost, efficacy and food safety. This is where a knowledgeable chemical supplier can assist in the development of effective cleaning regimes.

Chemical and Physical Reaction of Cleaning

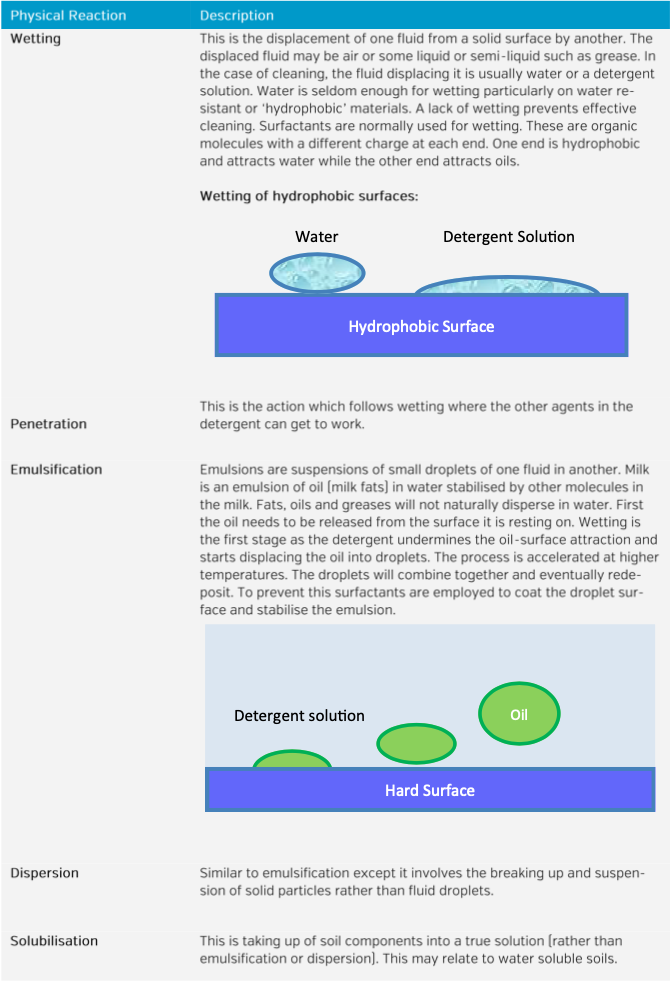

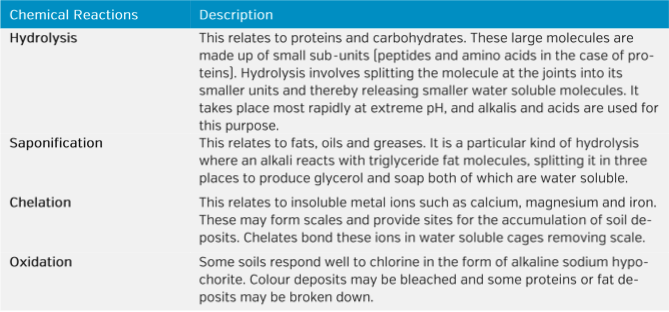

Detergency involves many reactions both physical and chemical. The main physical reactions are:

The main chemical reactions include:

Detergents

The nature and complexity of the detergent employed depends on the variation of soils, water hardness, the temperature of the method, plant surfaces and safety. Detergent suppliers typically have a range of detergents to be employed in varying and specific circumstances. The content of products will include:

- Alkalis: caustic soda, caustic potash, coronate, silicate, phosphate

- Acids: Phosphoric, nitric, citric, glycolic

- Chelates: EDTA, NTA, gluconate, glucoheptonate, citrate, polymeric

- Solvents: Isopropanol, propylene, butyl diglycol, ethers

- Surfactants: Anionic, cationic, non-ionic, amphoteric

- Inhibitors: Organic, inorganic

- Enzymes: protease, lipase, amylase

- Oxidising agents: hypochlorite, isocyanurates

- Stabilisers

- Viscosity modifiers

A detergent solution may contain between 2 and 15 components, blended carefully to specification. It is essential to work with an excellent supplier to identify the correct detergent for your operation correctly. This will save money in the long term as cleaning will be more effective. The failure of a product to work is usually not due to a low-quality product but rather the wrong one. Application and use are also important factors, and the right supplier will usually provide training in the correct use of the product.

Contact BRCT to get your food plant clean and to learn about what chemicals is required for effective cleaning solutions.

Reference : Safefood 360

Recent Posts

Could the standard of cleaning you are receiving be improved?

If you are not happy with your current cleaning contractor's service, don't just put up with it. Get yourself a company who will go the extra mile! Contact us now to help bring the standard of...

COVID-SECURE Disinfection cleaning & fogging services - Johannesburg. Fogging is a quick way to disinfect large areas and allow them to be returned to everyday use. We use a fogger machine...