BRCT Supply Services has been operating in this industry for over two centuries and has a proven track record with our customers for getting the job done and effectively.

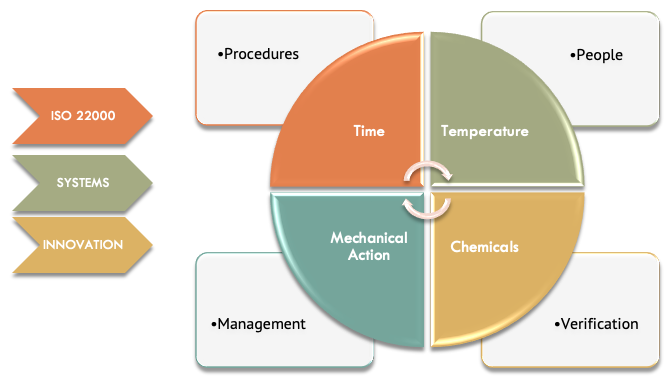

As a Food Safety and Sanitation Solutions company, we believe we can offer the following benefits to any food safety program:

- Improved Food Safety and Audit Scores.

- Innovative cleaning methods.

- Expertise with 20 years of experience within the food manufacturing environment.

- Comply with ISO Procedures.

- Improved food safety through:

- Effective management of the Sanitation Teams.

- Effective communication around food safety and sanitation through our homegrown software.

- Validation of the cleaning effectiveness.

- Rapid Testing technology.

- Compliance with Audit requirements.

Over the years we have formulated the winning recipe for our customers with the following areas form part of the Sanitation Service but not limited to:

Sanitation Meetings

Monthly Sanitation Meeting will be held with BRCT and our customers to review non-conformances, corrective actions and review cleaning processes.

We don’t just talk about it. We provide monthly cleaning reports generated from our internal cleaning management system as the basis of our feedback meeting.

Chemical usage

- Provide appropriate chemicals for the cleaning function in various areas.

- Detail a chemical product, usage and concentration strategy.

- Develop a chemical control policy.

- Develop chemical issuing and traceability procedure.

- Actively monitor the chemical usage and dilutions through

- On-site chemical verification

- Conductivity Meter

- Our cleaning staff receive regular training to keep our team up to date with the latest developments.

Training

- Well developed training matrix.

- BRCT provide detailed training records for onsite staff.

- All relevant stakeholders receive regular training on the latest development in the industry.

Health and Safety

- BRCT will sign the Health and Safety policy of our customer.

- Health and Safety Training of BRCT will be kept on file and regularly audited.

Electronic Database “iClean.”

BRCT has developed an online database that is used to manage, track and monitor the cleaning function and the non-conformances. This is a critical part of the cleaning function, which is collected to ensure the customers receives the desired results.

Regular Audits

Management will carry out regular audits of the cleaning function as part of our internal audit process with detailed action plans set up to be addressed both by BRCT and our customer. This will ensure effective management of the cleaning function and compliance with the required standards.

Food Safety Documentation

OPERATIONS:

- MEMO OF AGREEMENT

- MASTER CLEANING SCHEDULE. (MCS).

- WORK INSTRUCTIONS. (W.I.)

- SUPERVISOR JOB DESCRIPTION.

- CLEANER JOB DESCRIPTION.

TECHNICAL:

- CHEMICAL MSDS.

- CHEMICAL TECHNICAL DATA.

- CHEMICAL SUPPLIER SABS CERTIFICATION.

- CHEMICAL SABS 1828 & 1853 CERTIFICATION.

- CHEMICAL TEST METHODS.

- CHEMICAL DOSING.

- DISINFECTION NO RINSE POLICIES.

TRAINING:

- SUPERVISOR.

- CLEANER.

- WORKS INSTRUCTIONS (WI).

- CHEMICAL CONCENTRATION TESTING.

- CLEANING EQUIPMENT USE.

- BASIC HYGIENE FOR FOOD HANDLERS.

- CHEMICAL USE AND SAFETY.

- TRAINING CONTENT.

RECORDS 1:

- MICRO REPORTS.

- NON-CONFORMANCES.

- CORRECTIVE ACTION.

- CHEMICAL CONCENTRATIONS.

- VISIT REPORTS.

RECORDS 2:

January – December. CHECKLISTS (DAILY, WEEKLY, MONTHLY & OTHER)

Staff

Our Employees are valuable assets to our organization and key to the success of our business and our customers. Our staff is committed and understand the role they play in cleaning the respective area of business.

Equipment

We will ensure that our staff use the correct cleaning equipment in the area of cleaning. The use of cleaning equipment has evolved over the years. With the vast array of cleaning equipment that is available, we will match the correct equipment to respective areas. With the introduction of colour coding, it has revolutionised cleaning and the prevention of cross-contamination.

PPE

PPE stands for personal protective equipment. PPE means any device or appliance designed to be worn or held by an individual for protection against one or more health and safety hazards.

Training

All staff will undergo comprehensive training, including regular on the job training, including the following:

- Site Induction

- SOP Training

- Food Safety and Hygiene Training

- Chemical Use and Safety

- Relevant Occupational Health and Safety

- Effective use of equipment

Contract Term

Subject to the implementation plan, this contract will commence within 6-8 weeks of receipt of your official acceptance of our quotation. It will remain in force for six calendar months from the date of commencement.

Once this initial six month period has passed, then the contract will continue on a month to month basis.

Recent Posts

Could the standard of cleaning you are receiving be improved?

If you are not happy with your current cleaning contractor's service, don't just put up with it. Get yourself a company who will go the extra mile! Contact us now to help bring the standard of...

COVID-SECURE Disinfection cleaning & fogging services - Johannesburg. Fogging is a quick way to disinfect large areas and allow them to be returned to everyday use. We use a fogger machine...